PRECAST BRIDGE BEAMS

Pretensioned & Delivered Across South Africa

Precision-engineered bridge beams trusted by SANRAL, municipalities, and contractors nationwide.

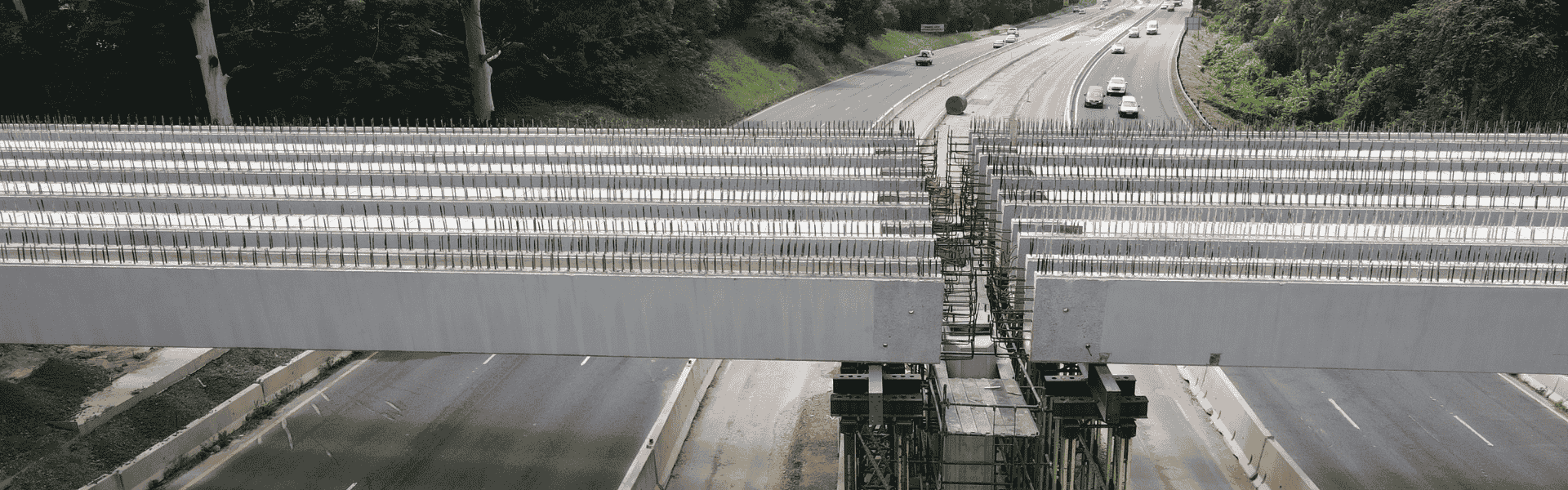

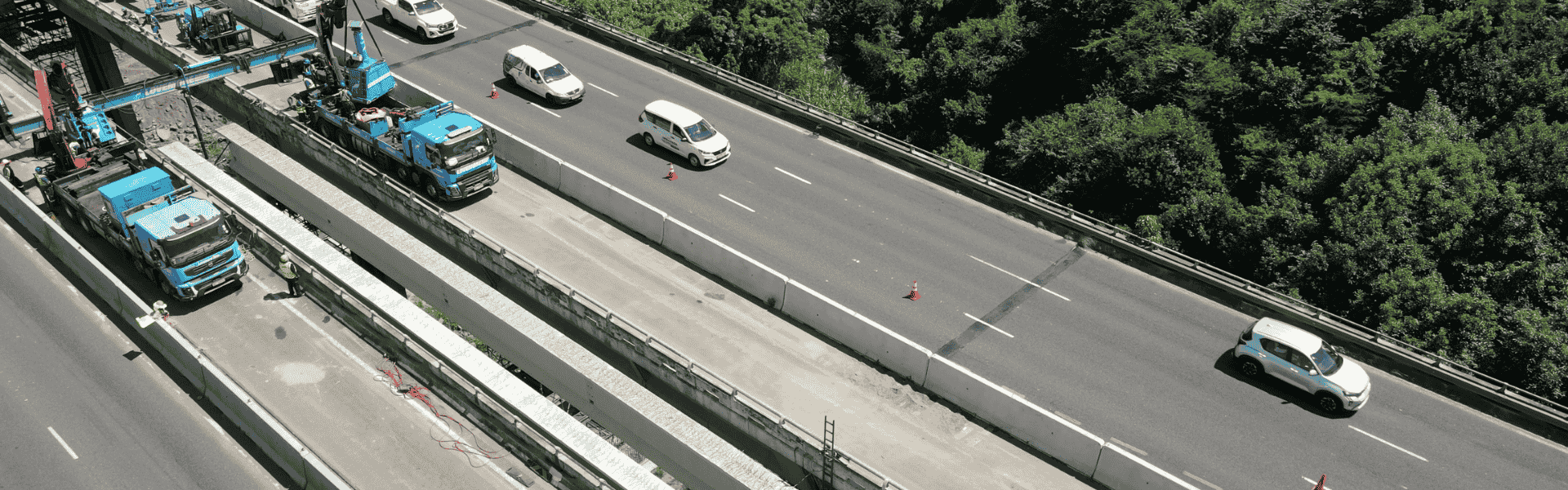

From highway overpasses to temporary diversions, Bedrock designs, manufactures, delivers, and rigs pre-stressed bridge beams across South Africa. Whether it’s a live-site lift or a remote span, our teams deliver accurate, high-tolerance components with proven logistics and safety systems in place.

Bedrock Group has recently delivered high-volume precast bridge beams for two landmark SANRAL infrastructure projects, reinforcing our role as a trusted structural partner in national road and rail upgrades.

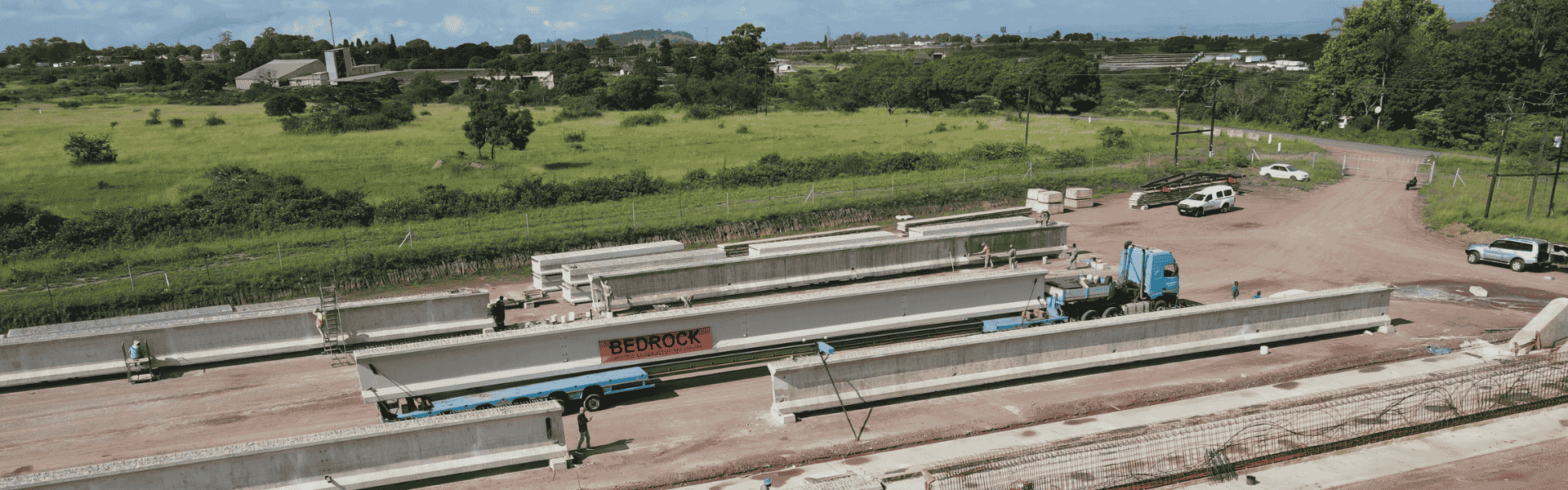

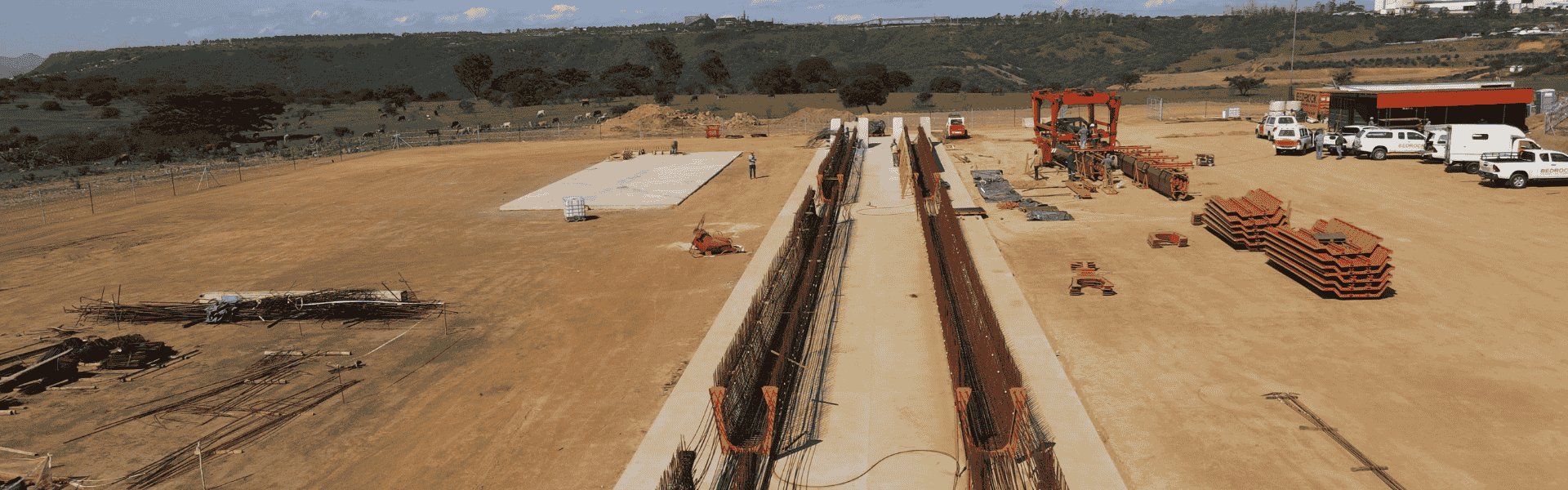

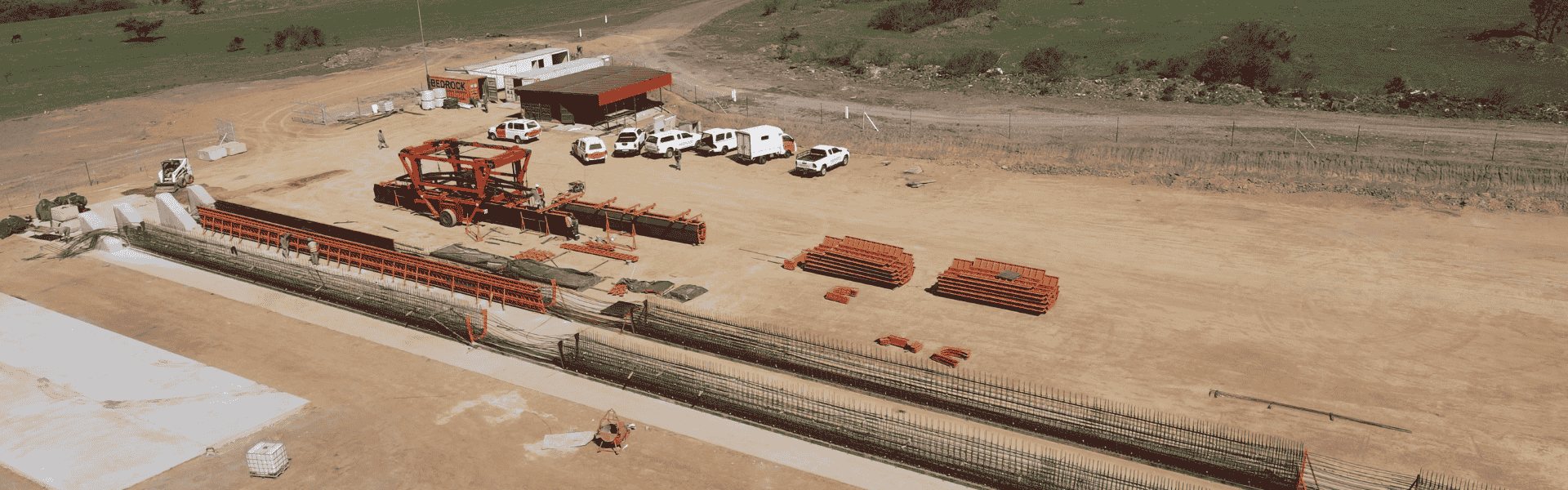

At the heart of this operation is our dedicated casting yard in Prime Industrial Estate, Cato Ridge—a purpose-built inland hub that allows for efficient manufacturing, staging, and transport of massive beams to sites across South Africa.

This site has become a key logistical node, with operations drawing attention across LinkedIn and the infrastructure community for its scale, speed, and coordinated rigging.

Bedrock Bridge Beams

Precast Bridge Beams – Pretensioned & Delivered Across South Africa

Reliable Bridge Beam Supply for Infrastructure That Lasts

Bedrock manufactures and delivers high-performance precast bridge beams throughout South Africa. From national roads to rural crossings, our beams are engineered for strength, durability, and site-specific requirements.

Whether you’re specifying pretensioned U-beams for a 33m SANRAL span, I-beams for a municipal bridge, or need a custom geometry for a complex interchange, Bedrock offers expert support from design to placement.

Types of Concrete Bridge Beams

CUSTOM

Engineered to suit unique spans, loading conditions, and geometry.

Looking for something else?

We can customise formwork for your project specifications.

Precision Manufacturing

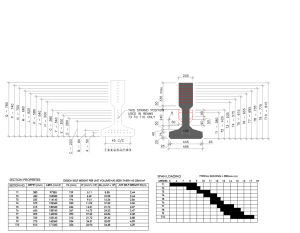

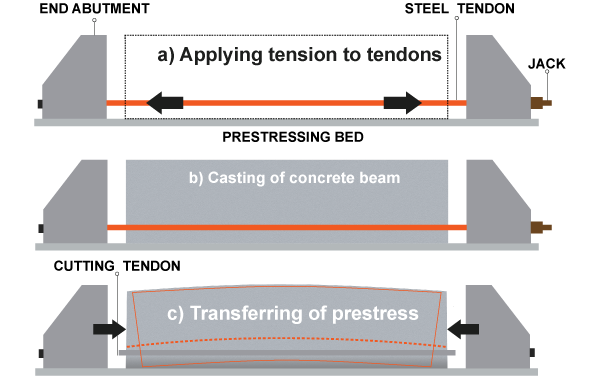

Pretensioned Concrete Beams Built to SANS Standards

- Manufactured in an ISO-compliant precast yard

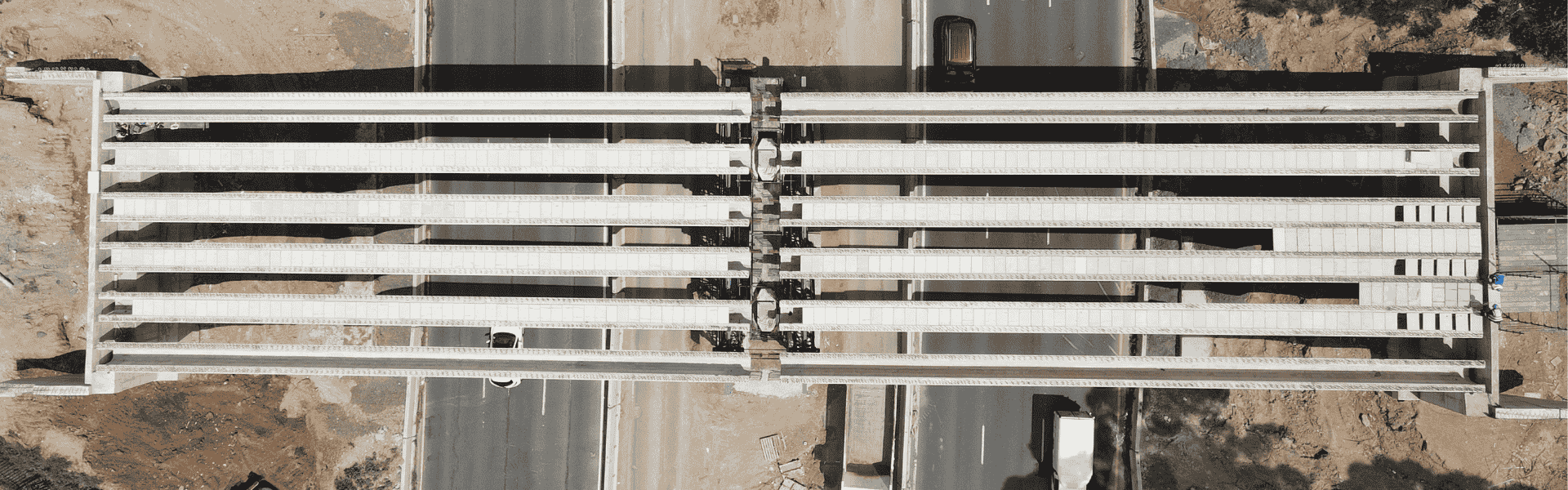

- Pretensioned concrete for reduced dead load and longer spans

- High-strength concrete for coastal, rural, and high-load environments

- Engineered in collaboration with structural specialists

- Compliance with SANS and SANRAL requirements

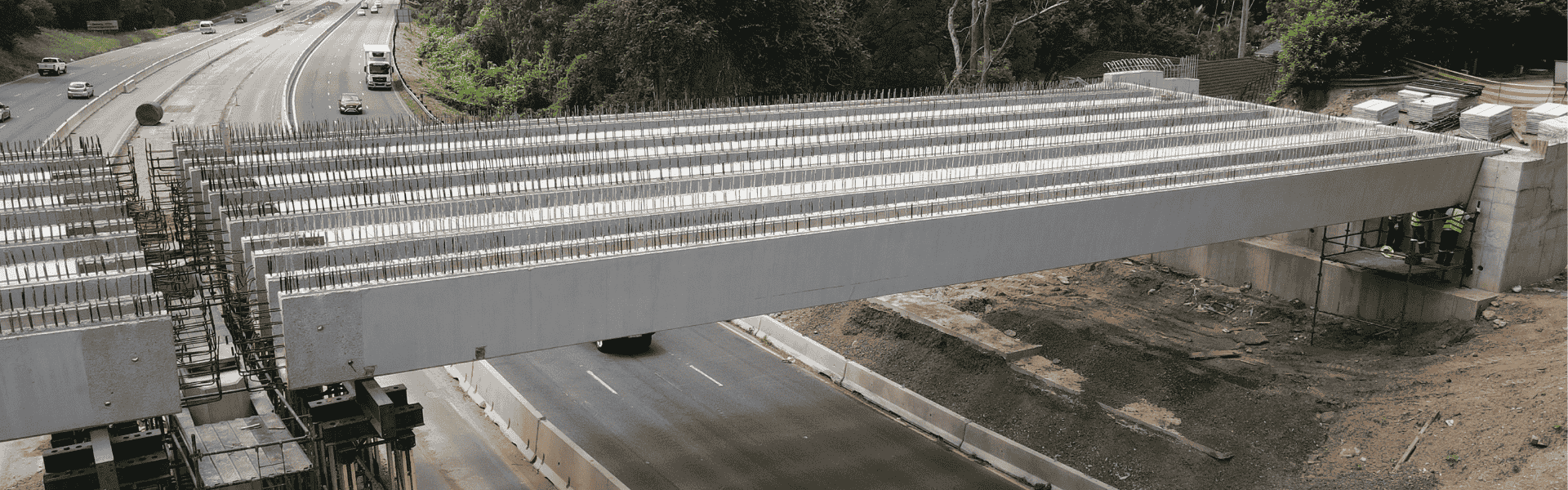

Project Spotlight: Paradise Valley Interchange – Durban (2024)

Project Duration: 6 Weeks | No of Beams: 12 | Beam Length: 33m | Weight: 45 tons

As part of the N3 realignment infrastructure upgrade, Bedrock has supplied and installed precast bridge beams for major viaduct and overpass structures across KwaZulu-Natal. Bedrock supplied and delivered twelve 33m pretensioned U-beams for the Paradise Valley Interchange as part of the N3 upgrade. Each beam weighed 45 tons and was delivered under SANRAL oversight in just 6 weeks.

Pretensioned Concrete Beams Built to SANS Standards

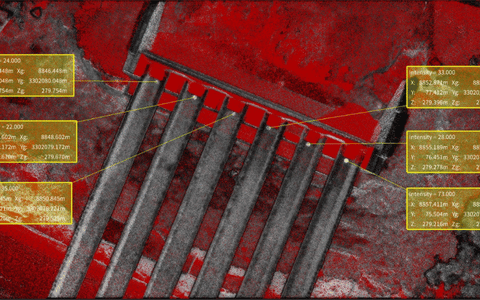

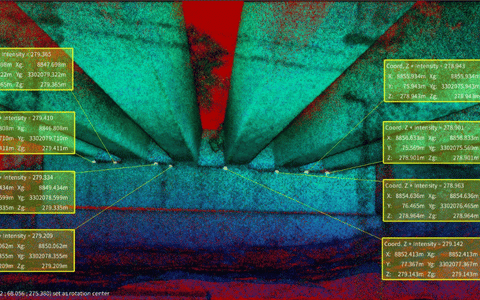

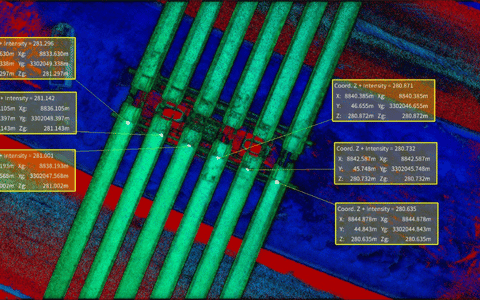

A recent LiDAR scan of the site confirmed that Bedrock’s precast bridge beams were delivered and installed precisely within specification. The point cloud data showed clean alignment, consistent camber, and accurate placement—reinforcing the reliability of both our casting and rigging processes.

Why choose Bedrock?

End-to-End Delivery Across South Africa

- Design → Manufacture → Transport → Site Placement

- Pretensioning capabilities for long-span U-beams

- Abnormal-load trucks and steerable dollies

- Temporary satellite or on-site yards available for major projects

- Night-time rigging & road closure experience

Precast bridge beams built for durability Heavy-duty transport and logistics in action Seamless installation on-site Bedrock Infrastructure is committed to engineering smarter solutions to move South Africa forward.